You may have noticed that this update is a little behind schedule and we want to assure you that we have been hard at work. Some of that work we can’t share at the moment or is just really boring. What we do want to share with this update are some of the challenges we’ve faced during these last few weeks and what we’ve learned through testing the PL1 in the shop and in the mountains.

Bench Testing

Bench testing has been critical for continuing to develop the product over the summer. Having a reliable bench test allows us to test different design configurations much more efficiently than field testing, and will be crucial for quality assurance when we move to production.

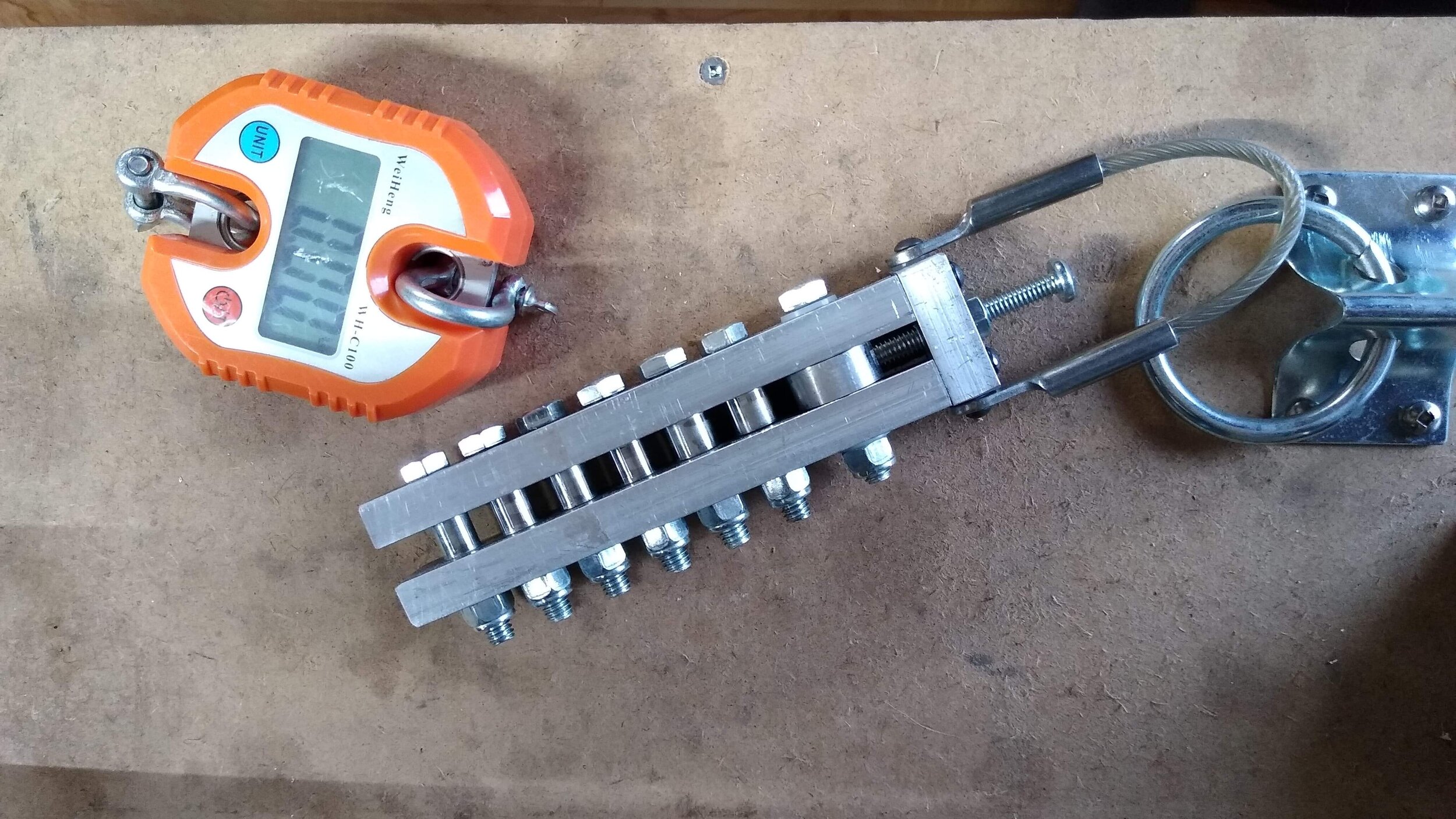

In order to do this, I built a tensioning device that can allow rope to pass through it continuously while providing an adjustable level of resistance. The design I ended up with looks and works a bit like a rack style rope descender, and relies on the same principles (as does the PL1 drive system).

The bench tests have clearly revealed that not all 550 paracord is created equal. The lesson we’ve learned is that we have to be very careful where we source our rope. Generally, the failures are not due to pure tensile overload, but to abrasion. We’ve found that paracord with sheathing that is looser over the core strands is more likely to fail.

We have found two main solutions to this problem. The first is to find a reliable source of high quality paracord, which we believe we have with a Canadian supplier. Another option is to use a solid braid nylon cord instead. While the solid braid is very robust in terms of abrasion resistance, the downside is that it is a bit stiffer and heavier. It’s worth noting that in the event of a sudden jam, either rope is likely to fail, but this is not likely to occur in actual use.

Challenges

This is a small operation on a tight budget. We can build many of the parts in house, but others have to be ordered from outside. Because of this, when things go wrong it can mean significant delays.

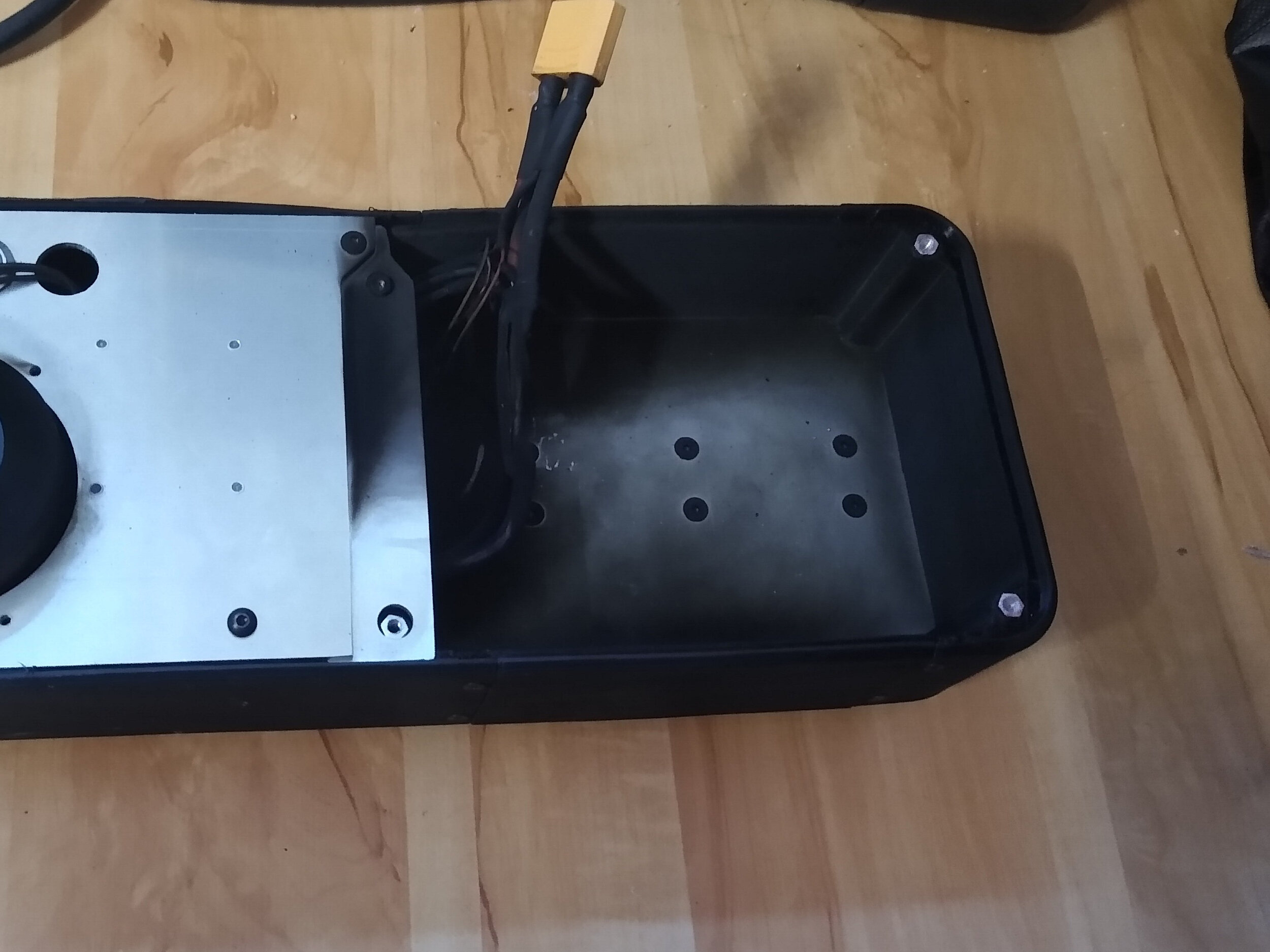

I’ve included a recent example of things going wrong. While setting up the latest alpha prototype, a wiring issue resulted in significant damage to a number of components. Luckily a number of critical parts were spared.

Field Testing

Despite the setbacks, we were able to get a unit setup for testing last weekend. Snow is limited and harder to reach near the coast right now, so we decided to travel inland to Sun Peaks, which looked like it had just enough snow for us to get some decent testing in.

A demonstration of how to hook up the PL1 after your run

The prototype we tested with uses an older version of the frame, but the most recent gearbox and motor configuration.

This was a fairly conservative test. We tested the product on a “blue” run, with the line starting on a light slope and then descending to a more moderate incline. Replacement rope had not yet arrived before we left, so we were testing with a rope section that was approximately 400ft - 500ft long.

While it wasn’t a rigorous test, it was important an one. It was the first test on snow for this configuration and it helped us better understand the product experience. We’re excited to get a lot more testing done as the snow starts to fall in BC.

With more funding we could speed up the testing process significantly. It would help us keep more spare parts on hand and expedite any parts that need shipping. As we gear up for Beta prototyping we are actively looking for investment and are encouraging any interested parties to reach out.

Stay safe,

Robbie Button - P.Eng, Founder